FAQ'S

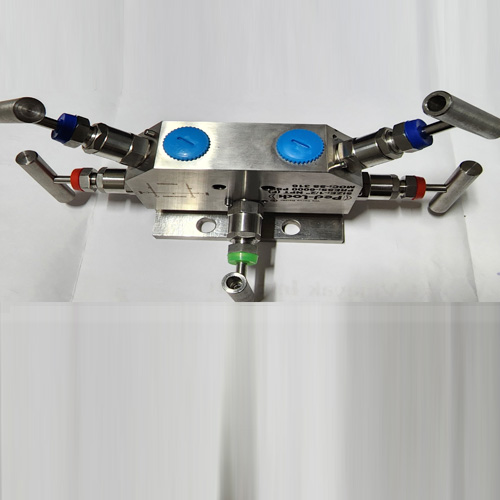

What is a manifold valve used for?

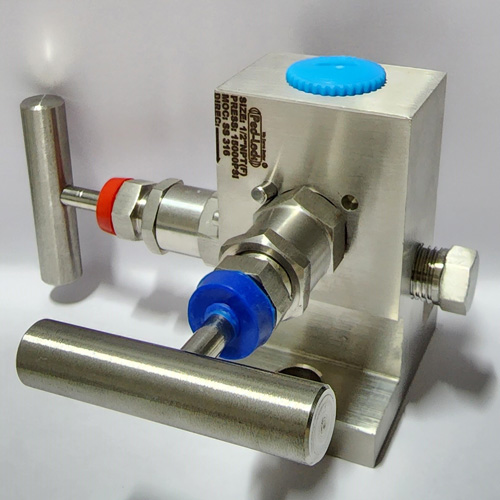

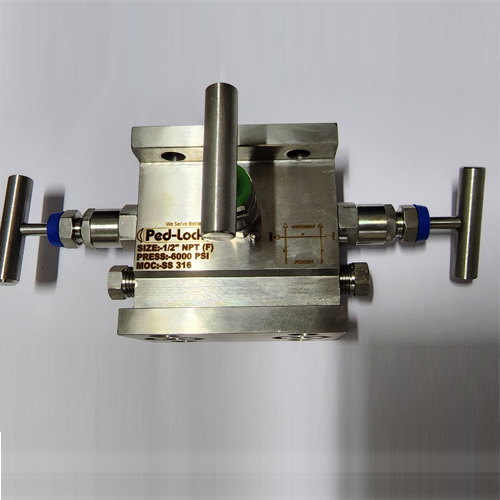

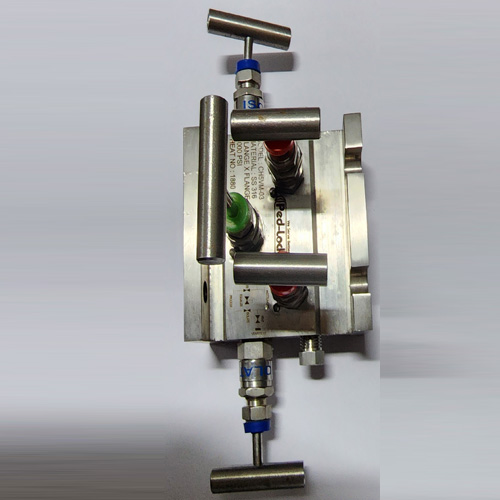

Manifold valves are used to control, isolate, and direct the flow of fluids or gases in high-pressure systems. They are essential for isolating sections of the system for maintenance, calibration, or venting.

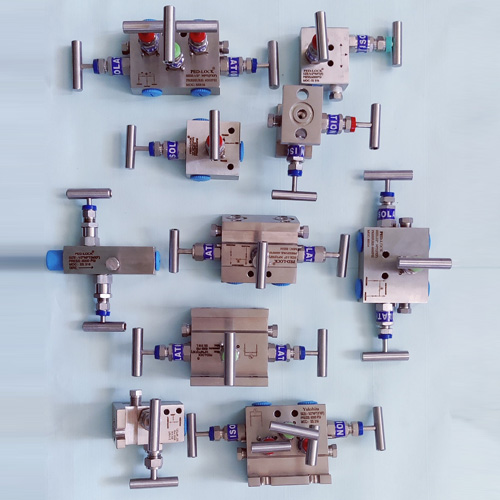

What are the types of manifold valves?

Common types include 2-way, 3-way, and 5-way manifold valves. Each type has different functions, such as isolation, equalization, and venting, to accommodate specific needs in fluid or gas management.

Salient Features

Specifications

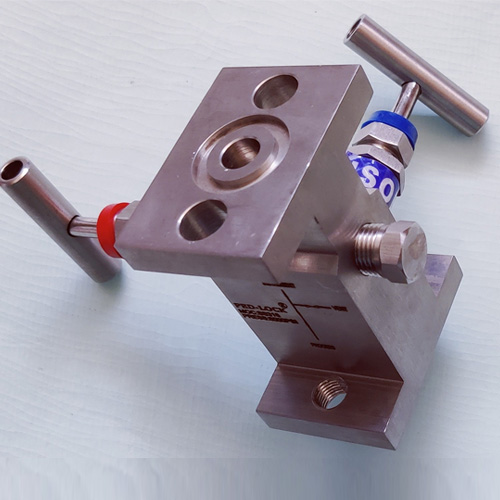

What materials are manifold valves made from?

Manifold valves are typically made from stainless steel, brass, or other corrosion-resistant materials to withstand high pressures and various environmental conditions.

What are the benefits of using a manifold valve?

Benefits include improved safety, easy maintenance, reduced risk of leaks, and more efficient calibration and testing, making them valuable in systems requiring precision and control.