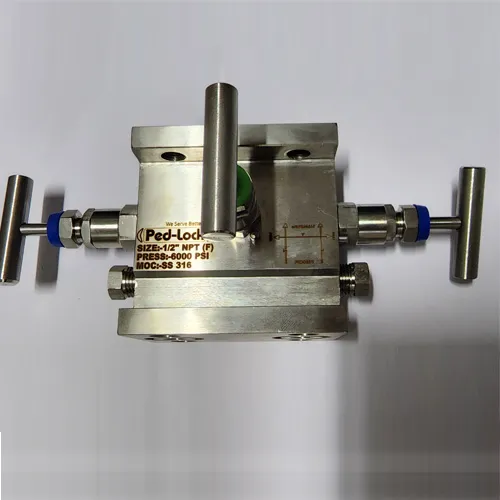

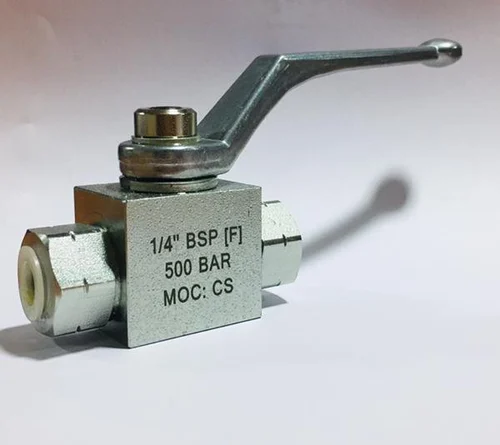

We are most prominent manufacturer, supplier and exporter of Flow

Controls Valve in USA. A Flow Control Valve serves as a

critical component in fluid-based systems, designed to regulate and control

the flow rate of fluids within a wide range of applications. Employing a

variable orifice design, these valves allow operators to precisely adjust

the opening size, providing control over the speed and efficiency of fluid

flow. A popular kind of flow control valve is the throttle valve, which

modulates the orifice with tapered needles or cones to allow for fine

control in pneumatic and hydraulic systems. There are two types of flow

control valves: pressure-compensated and non-compensated. The former

automatically adjusts to variations in pressure in order to keep the flow

rate comparatively constant. Numerous sectors, such as chemical manufacture,

water distribution, oil and gas processing, hydraulic and pneumatic systems,

and water distribution, use these valves. Flow control

valves, whether manually or automatically operated, improve

efficiency, safety, and precision in fluid handling processes while

guaranteeing accurate and constant flow regulation. This helps to optimize

system performance.